Product Range:

Large Size Butterfly Valve

Laminated Seal Butterfly Valve

Hard Seal Butterfly Valve

Stainless Steel Butterfly Valve

1)Suitable Medium: Water, sewage, sea water, air, foodstuff, oil etc.

2)Working Temperature: -20° C~450° C

3)Operator: Suitable for handles(dn50~300), gear operators, electric and pneumatic control actuators.

4)wafer type large size butterfly valve

5)Connection form: Wafer

6)Seal form: Auto sealed

7)Material of seal surface: Metal sealed

8)Structure: Center sealing

9)Body material: Cast steel, ductile iron, stainless steel304/316, carbon steel

10)Disc material: Cast steelstainless steel 304/316, aluminum bronze

11)Shaft material: Stainless steel 304/316/416

12)Seal ring material: SS304, hard alloy

13)Color: Depends of the request

14)Packing: Plastic inside and Plywood case outside

Besides butterfly valve, we can also offer gate valve, ball valve, globe valve, check valve, safety valve and so on. If you have any demand, pls kindly send us the inquiry. We'll try our best to support you.

The Solid Quarter Turn Valve is a ZERO LEAKAGE Metal Seated Valve that features a triple eccentric, non-rubbing conical metal seat which offers tight shut off for many thousands of cycles. The seating of the valve is actually enhanced by continued operation. These unique design features combine to give the Solid valve the following attributes: Bidirectional tight shut off on services ranging from cryogenic to 600 degree centigrade, limitations being governed by the selection of body, disc and seal materials. The Solid is inherently fire safe which means the valve can offer ZERO LEAKAGE before, during and after the fire as there are no soft components in the valve seating areas. Simple direct mounted on ISO standard mounting flanges. The Solid has good control characteristics through most of its travel, and with the addition of a positioned will give control suitable for many applications. The standard valve is wafer pattern conforming to API 609 dimensions and has enormous space and mass savings when compared with other types of valves. Solid valves are also available in full lug and flanged patterns with dimensions in accordance with ISO 5752 or API 600, making them interchangeable with gate, ball and plug valves. As can be seen from the illustration, this design utilizes a wedging action to put the laminated seal ring in compression when in contact with the body seat. Further, as the seal ring has clearance between disc and the inside of the lamellar it is able to self align and also flex to absorb stresses that might be induced by temperature fluctuations or pipeline movement.

| CarbonSteel/ENC | |||||

| The material selection will determine the suitability of the valve for the service media and the expected temperature range. The responsibility for final material selection rests with the customer. We can, however, suggest suitable combinations based on our experience. The following table shows the current material selection that is available, but special materials can be substituted to suit particular applications |

|||||

| Body and disc | Seat | Spindle and keys | Laminated seal ring | Bearing | Packing and Gaskets |

| CarbonSteel/ENC | Stainless steel | AISI 431 | AISI 304 | Stainless chrome or nickle plated |

Graphite/gaphoil |

| Stainless steel | Stellite 21 or Colmonoy wearresistant facings |

17-4ph AISI 630 |

AISI 316 | Stellite shell | Graphoil |

| Acid resistant alloy steels |

Special alloys | FAL 223 | Hardened stainless | Graphite with Bearing prot graphoil |

|

| Steels for high and cryogenic temperatures |

Sintered PTFE and bronze |

||||

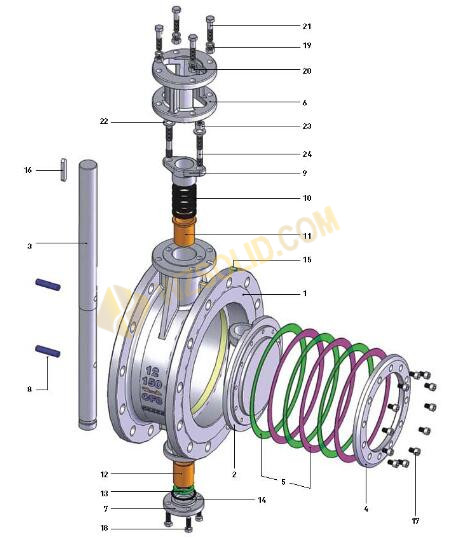

| Structure of triple off-set metal seal High-Preformance Butterfly Valve | ||||

| Item | Description | Temperature-29~425º | Temperature-196~538º | Temperature-196~538º |

| CS | CF8 | CF8M | ||

| 1 | BODY | A216WCB | A351 CF8 | A351 CF8M |

| 2 | DISC | A216WCB | A351 CF8 | A351 CF8M |

| 3 | SHAFT | A182 F6A | A182 F304 | A182 F316 |

| 4 | RETAINER | A105 CS+ENP | SS 304 | SS 316 |

| 5 | SEAL RING | SS316+FLEX GRAPHITE | SS316+FLEX GRAPHITE | SS316+FLEX GRAPHITE |

| 6 | YOKE | A216WCB | A216 WCB+ENP | A216 WCB+ENP |

| 7 | BOTTOM COVER | A105 CS | SS 304 | SS 316 |

| 8 | HINGE PIN | A276 410 | SS 304 | SS 316 |

| 9 | PACKING GLAND | A216WCB | A351 CF8 | A351 CF8M |

| 10 | PACKING | FLEX GRAPHITE | FLEX GRAPHITE | FLEX GRAPHITE |

| 11 | FRONT AXIAL BUSHING | B148 C95500 | B148 C95500 | B148 C95500 |

| 12 | REAR AXIAL BUSHING | B148 C95500 | B148 C95500 | B148 C95500 |

| 13 | SPLIT RING | SS 304 | SS 316 | SS 316 |

| 14 | SEAL GASKET | SS304+FLEX GRAPHITE | SS304+FLEX GRAPHITE | SS304+FLEX GRAPHITE |

| 15 | LOOSE-PROOF PIN | A276 410 | SS 304 | SS 304 |

| 16 | KEY | AISI 1045 | AISI 1045 | AISI 1045 |

| 17 | SCREW | A193 B8 | A193 B8 | A193 B8M |

| 18 | BOLT | A193 B7 | A193 B8 | A193 B8M |

| 19 | SPRING GASKET | AISI 1566 | AISI 1566 | AISI 1566 |

| 20 | NUT | A194 2H | A194 8 | A194 8M |

| 21 | BOLT | A193 B7 | A193 B8 | A193 B8M |

| 22 | GASKET | A105 CS | SS 304 | SS 316 |

| 23 | NUT | A194 2H | A194 8 | A194 8M |

| 24 | STUD | A193 B7 | A193 B8 | A193 B8M |

| The illustrations in this catalogue are subject to modifications without notice. NOTES: 1. The above is the general specification. If special requirements by clients, we can do a proper material selection according to working condition. 2. For the valves used for special working condition, please query with our engineers for material and other details. |

||||

The Solid Series Metal Seated Valve's triple eccentric sealing design offers the user a “ZER O LEA KAGE” isolating valve for use in a variety of applications in a wide range of industries:

• Mining - Service Water

• Petroleum

• Chemical and Process Plants

• Gas Production and Transportation

• Off-shore Oil and Gas Platforms

• Pulp and Paper

• Emergency Shut Down Valves (ESDs)

• Steel Mills

• Sugar Mills

• Pipeline Isolation

• Low Pressure Steam

• Hot Gases (including Flue Gas)

• Cryogenic Services

• High Cycle and Switching Valves

• Water Treatment and Distribution

• Power Generation

The Solid Design is ideal (and proven) for use in Mining Service water applications:

• Metal Seating provides longer life

• Compact design

• Ease of 90° operation

• From 16bar to 150bar pressure ratings

• Ideal for Actuated Pump control as it has linear flow Characteristics

Metal seated, non-rubbing, “Zero Leakage”, bidirectional

• Non-rubbing rotation

• Anti-blowout shaft

• Zero fugitive emission

• Resilient metal seal

• Torque seated

• Inherently fire safe

• Sizes 100mm – 1000mm

(other sizes on application)

• Class ratings ANSI 150 through 900

• PN 10 to PN 150