Swing check valve also known as one-way valve or check valve, its role is to prevent the media flows back in the pipeline. Opening and closing parts by the power of media flow. Check valves are automatic valves, mainly for the medium one-way flow of the pipeline, allowing the media to flow in one direction, to prevent accidents. This kind of valve should be installed horizontally in the pipeline. Swing check valve is suitable for nominal pressure PN1.0MPa~42.0MPa, Class150-2500; nominal diameter DN15~1200mm, NPS1/2~48; working temperature 196~540 degrees Celsius on the pipeline, to prevent the media back. Through the use of different materials (WCB, CF8 (M), CF3 (M), 1Gr5Mo, 15CrMo1V, can be applied to water, steam, oil, nitric acid, acetic acid, strong oxidizing medium and urea and other media. They are mainly used in petroleum, chemical, pharmaceutical, fertilizer, electricity and other pipelines.

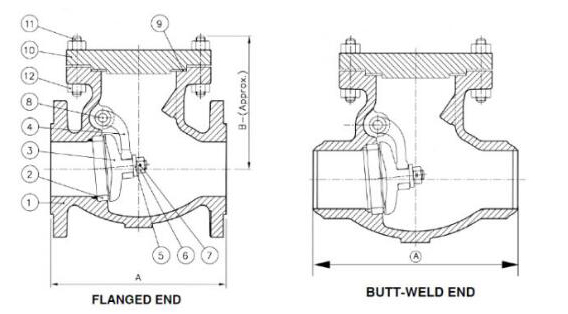

Swing check valve with the built-in rocker swing structure, all opening and closing parts are arranged in the valve body of the valve, the valve does not penetrate, in addition to the seal gasket and seal ring with flange, overall no leak, to prevent leakage of the valve may be. Swing check valve rocker arm and disc connection with spherical structure, so that the valve flap in the range of 360 degrees have a certain degree of freedom, there is an appropriate micro position compensation.Suitable for clean medium, not suitable for containing solid particles and viscosity medium

Model NO.: H44H-150LB-DN150

Connection Form: Flange

Pressure: High Pressure

Sealing Form: Gland Packings

Standard: ANSI

Certification: ISO9001:2008,JIS,Kc,API

Seat: Stellited

Trademark: SOLID

Specification: CE, SGS, KS

HS Code: 8481300000

Material: Cast Steel

Structure: Swing

Function: Ddcv Double Lobe, Nrvr Silence

Flow Direction: Reversing

Application: Industrial Usage, Water Industrial Usage, Household Usage

Size: Dn100

Disc: 304

Transport Package: Wooden Carton

Origin: China

| DN mm | in | L | D | D1 | D2 | b | n-φd | H | D0 | W(kg) |

| 50 | 2 | 203 | 155 | 120 | 100 | 16 | 4-19 | 165 | 165 | 17 |

| 65 | 21/2 | 216 | 175 | 140 | 120 | 18 | 4-19 | 175 | 175 | 25 |

| 80 | 3 | 241 | 185 | 150 | 130 | 18 | 8-19 | 190 | 190 | 29 |

| 100 | 4 | 292 | 210 | 175 | 155 | 18 | 8-19 | 215 | 215 | 50 |

| 150 | 6 | 406 | 280 | 240 | 215 | 22 | 8-23 | 265 | 265 | 85 |

| 200 | 8 | 495 | 330 | 290 | 265 | 22 | 12-23 | 320 | 320 | 150 |

| 250 | 10 | 622 | 400 | 355 | 325 | 24 | 12-25 | 365 | 365 | 240 |

| 300 | 12 | 698 | 445 | 400 | 370 | 24 | 16-25 | 415 | 415 | 35 |

| 350 | 14 | 787 | 490 | 445 | 415 | 26 | 16-25 | 460 | 460 | 460 |

| No. | Part Name | Material |

| 1 | Body | ASTM A216 WCB |

| 2 | Body Seat Ring | ASTM A105+HF |

| 3 | Disc | ASTM A216 WCB+13CR |

| 4 | Hinge | ASTM A216 WCB |

| 5 | Disc Washer | 13CR |

| 6 | Disc Nut | SS304 |

| 7 | Disc Nut Pin | 13CR |

| 8 | Hinge Pin | 13CR |

| 9 | Gasket | ASTM A308 |

| 10 | Cover | ASTM A216 WCB |

| 11 | Stud | ASTM A193 B7 |

| 12 | Stud Nut | ASTM A194 2H |