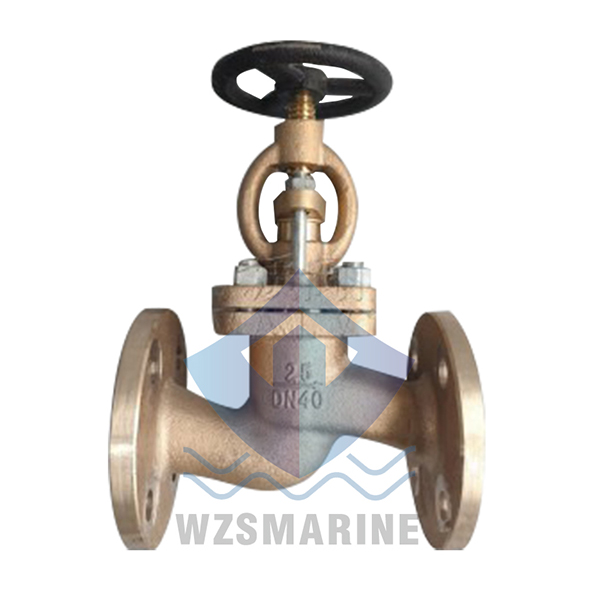

The function of flange bronze check valves is to only allow medium to flow in one direction and prevent flow in that direction. In general, this type of valve operates automatically, and under the pressure of fluid flowing in one direction, the valve disc opens; When the fluid flows in the opposite direction, the valve seat is affected by the fluid pressure and the self closing of the valve disc, which also cuts off the flow. Flange bronze check valves include swing type flange bronze check valves and lift type flange bronze check valves. The swing flange bronze check valve has a hinge mechanism and a gate like disc that freely rests on the tilted valve seat surface. In order to ensure that the valve disc can reach the appropriate position on the valve seat surface every time, the valve disc is designed in a hinge mechanism, so that the valve disc has sufficient swing space and truly and comprehensively contacts the valve seat.

The valve discs of flange bronze check valves can all be made of metal, or they can be embedded with leather, rubber, or synthetic covers on the metal, depending on the performance requirements. The swing flange bronze check valve does not affect fluid pressure when fully opened, so the pressure drop through the valve is relatively small. The disc seat of the lifting flange bronze check valve is located on the sealing surface of the valve seat on the valve body. Except for the valve disc, which can freely rise and fall, the rest of the valve is like a globe valve. Fluid pressure lifts the valve disc from the sealing surface of the valve seat, and medium backflow causes the valve disc to fall back onto the valve seat, cutting off flow.