Flange cast steel stop check valve, also known as one-way valve or check valve, is used to prevent the medium in the pipeline from flowing back. The bottom valve for water pump suction and closing also belongs to the check valve category. A valve that relies on the flow and force of the medium to open or close itself, in order to prevent the medium from flowing back, is called a check valve. Check valves belong to the automatic valve category and are mainly used in pipelines with unidirectional flow of media. They only allow media to flow in one direction to prevent accidents. The installation method for flange cast steel stop check valves is as follows:

1. The installation position, height, and inlet and outlet direction of the flange cast steel stop check valve must meet the design requirements. Attention should be paid to the direction of medium flow consistent with the arrow direction marked on the valve body, and the connection should be firm and tight.

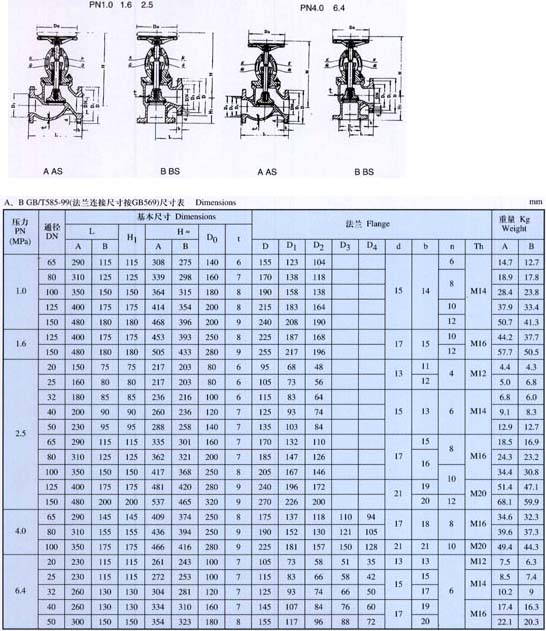

2. Before installation, a visual inspection must be conducted on the flange cast steel stop check valve. The nameplate of the valve should comply with the current national standard "General Valve Markings" GB 12220. For work pressure greater than 1. Valves with a pressure of 0 MPa and a cutoff function on the main pipe should undergo strength and tightness tests before installation, and can only be used after passing the tests. During the strength test, the test pressure is 1% of the nominal pressure. 5 times, with a duration of no less than 5 minutes, and the valve casing and packing should have no leakage, it is considered qualified. During the tightness test, the test pressure is 1% of the nominal pressure. 1 time; The duration of the test meets the requirements of GB 50243.

3. Do not allow flange cast steel stop check valves to bear weight in pipelines. Large check valves (aetv One way valves) should be independently supported to prevent them from being affected by the pressure generated by the pipeline system.