Cast Steel and Cast Iron/Ductile Iron Butterfly Valves

Basic Info

| Model NO.: | CS/CI BV |

| Connection Form: | Flange |

| Seal Form: | Auto Sealed |

| Work Pressure: | Low Pressure (Pn<1.6mpa) |

| Material of Seal Surface: | Soft Sealed |

| Application: | Oil, Water, Gas |

| Size: | 2" to 60" or Larger |

| Sealing: | Metal Seat, Soft Seat |

| Disc Type: | Centric |

| Trademark: | SOLID INDUSTRY |

| Specification: | CE |

| HS Code: | 8481 |

| Driving Mode: | Manual, Electric, Pneumatic |

| Structure: | Double-Eccentric Sealing |

| Valve Stem: | Normal |

| Working Temperature: | Medium Temperature (120°C<T<450°C) |

| Valve Body: | Casting |

| Material: | Cast Iron, Ductile Iron, Carbon Steel, Stainless Steel |

| Type: | Wafer Type, Lugged Type, Double Flanged Type |

| Operation: | Lever, Gear |

| Design Standard: | API609 |

| Transport Package: | Plywood case |

| Origin: | China |

Product Description

Cast steel and cast iron Butterfly Valves, wafer butterfly valve, lugged butterfly valve, double flanged butterfly valve, high performance butterfly valve

Standard compliance

1)Design and manufacture:API609

2)Test and inspection:API598

3)Face to face dimensions:API609, ANSI B16.10

4)End flange dimensions:ANSI B16.5, B16.47 SERIES A & SERIES B, DIN, BS, JIS

5)Butt-welding end:ANSI B16.25

Specifications:

1)Size:DN50 ~ DN4000

2)Class:150LB to 600LB

3)Type:Wafer type, lugged type, flanged type, center line/double eccentric/triple offset type, metal seated or soft seated, high performance

4)Material:WCB, WCC, WC6, WC9, C5, C12, CF8, CF8M, CF3, CF3M, CN7M, LCB, LCC, DUPLEX SS, MONEL, ALLOY 20, cast iron etc.

5)Operation: lever and gear operation

Description:

Wafer type or lugged type

Design and manufacture: MSS SP-67, API 609

Test and inspection: API 598 .

Flanged end: ANSI B16.1, BS4504, ISO2084 and

Flanged end: DIN2501 etc.

Top flange: ISO5211

Center line butterfly valve

Resilient seat

Shaft: Round, double D or square type

Size: 2" ~ 32" (DN50 ~ 800)

Working pressure: 1.0MPa / 1.6MPa / Class125

Operator: lever, gear, electric or pneumatic actuator

Standard materials of parts

| Body | Grey iron, Ductile iron, Cast steel, Stainless steel |

| Disc | Ductile iron, Aluminum bronze, Stainless steel |

| Stem | Stainless steel |

| Bushing | Lubricated bronze, PTFE |

| Seat | BUNA, EPDM, Neoprene, PTFE, NR, NBR, Hypalon, VITON |

| Pin | Stainless steel |

| O-ring | BUNA, EPDM |

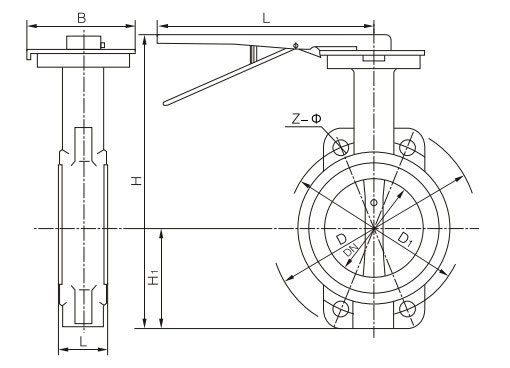

Dimensions (in mm & inch) and weight

| Size | A | B | C | L | E | F | kgs | |

| mm | inch | |||||||

| 50 | 2" | 161 | 80 | 42 | 32 | 57.15 | 12.6 | 2.5 |

| 65 | 2.1/2" | 175 | 89 | 44.7 | 32 | 57.15 | 12.6 | 3.2 |

| 80 | 3" | 181 | 95 | 45.2 | 32 | 57.15 | 12.6 | 3.6 |

| 100 | 4" | 200 | 114 | 52.1 | 32 | 69.85 | 15.7 | 4.9 |

| 125 | 5" | 213 | 127 | 54.4 | 32 | 69.85 | 18.92 | 7 |

| 150 | 6" | 226 | 139 | 55.8 | 32 | 69.85 | 18.92 | 7.8 |

| 200 | 8" | 260 | 175 | 60.6 | 45 | 88.9 | 22.1 | 13.2 |

| 250 | 10" | 292 | 203 | 65.6 | 45 | 88.9 | 28.45 | 19.2 |

| 300 | 12" | 337 | 242 | 76.9 | 45 | 107.95 | 31.6 | 32.5 |

| 350 | 14" | 368 | 267 | 76.9 | 45 | 107.95 | 31.6 | 41.3 |

| 400 | 16" | 400 | 298 | 86.5 | 51.2 | 158.75 | 33.15 | 61 |

| 450 | 18" | 422 | 318 | 105.6 | 51.2 | 158.75 | 38 | 79 |

| 500 | 20" | 480 | 349 | 131.8 | 64.2 | 185.75 | 41.15 | 128 |

| 600 | 24" | 562 | 440 | 152 | 70.2 | 215.9 | 50.65 | 188 |

| 700 | 28" | 624 | 520 | 163 | 72 | 254 | 55 | 284 |

| 800 | 32" | 672 | 591 | 188 | 82 | 254 | 55 | 713 |

The centric butterfly can be made of cast steel, stainless steel or alloy steel. It is widely used in pharmaceutical, chemical, petroleum, textile, papermaking and other industries, the working environment is generally between 80 to 120 degrees, following a brief introduction to the midline of the folder type butterfly valve features:

(1) the seat can be replaced, reliable sealing performance to achieve two-way seal zero leakage; (2) special seal structure under high temperature and cold working conditions, sealing without stress and deformation, can achieve zero leakage;

(3) adopt axial positioning device, solve the difficult problem of leakage at the axial seal and the sealing surface easy wearing, drive actuator can be install at any direction.