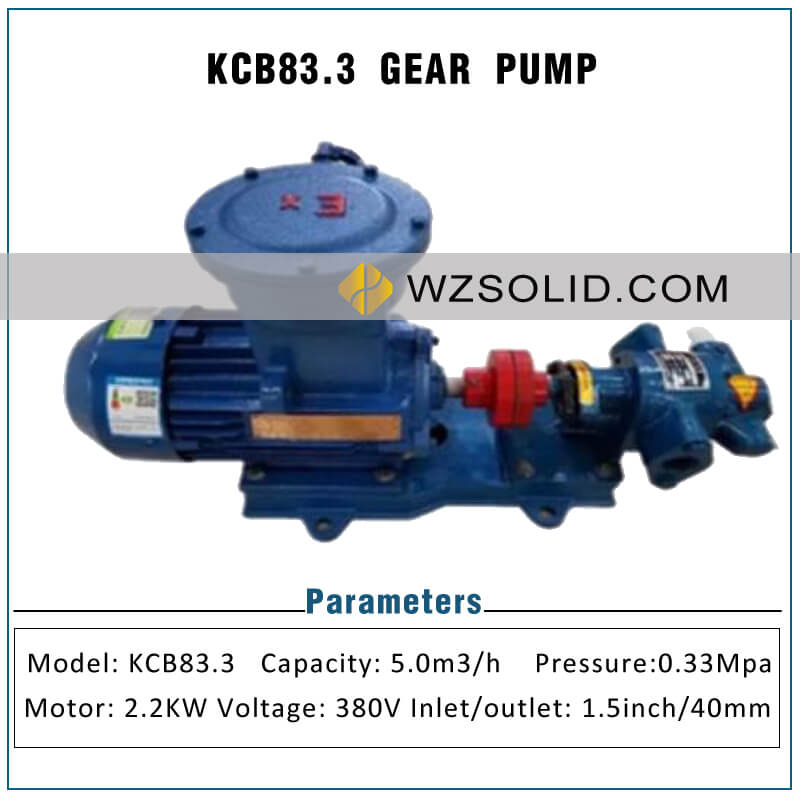

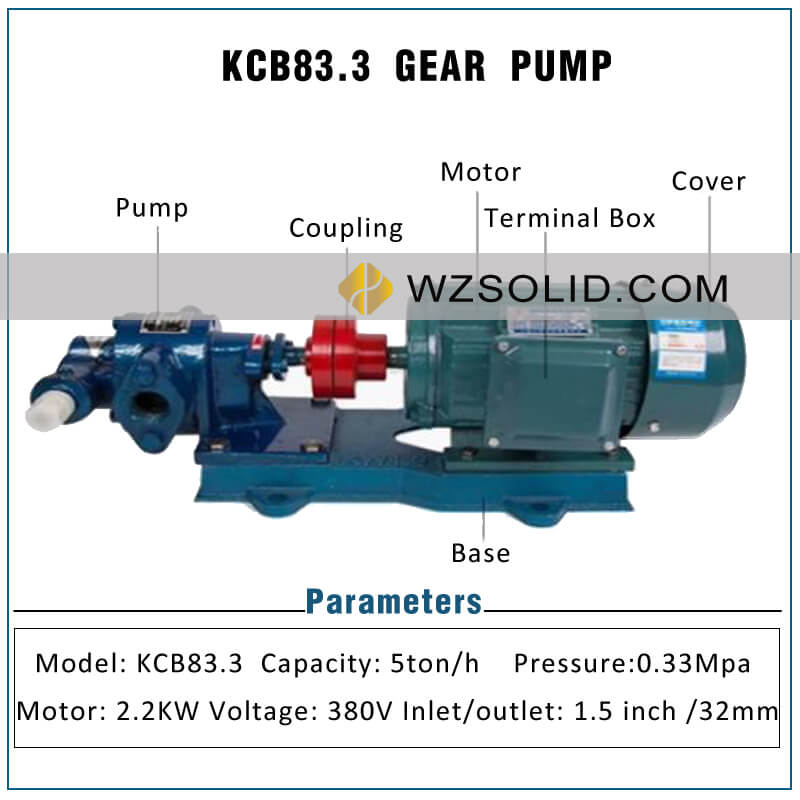

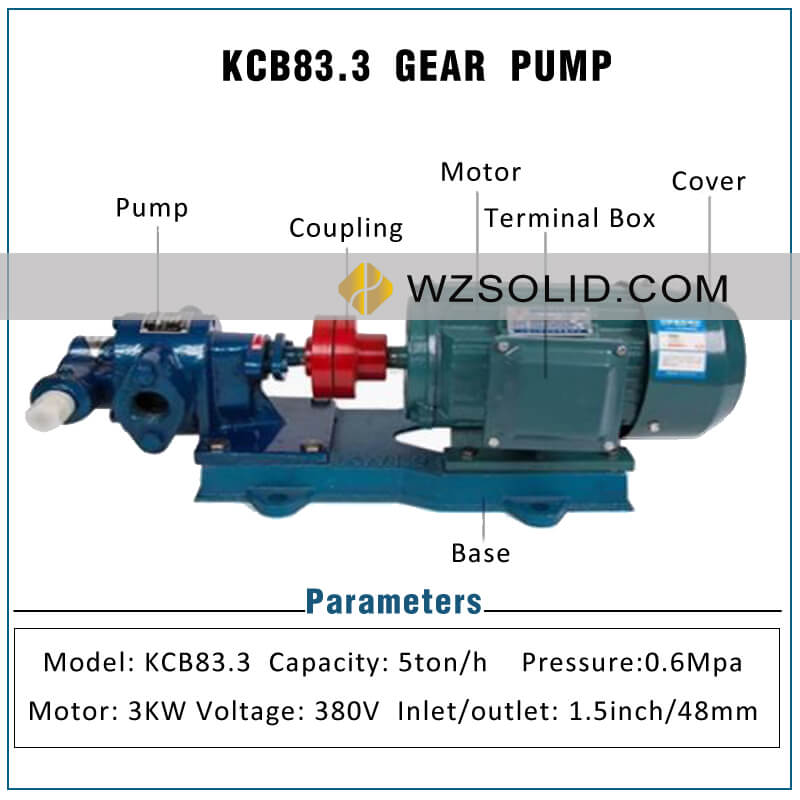

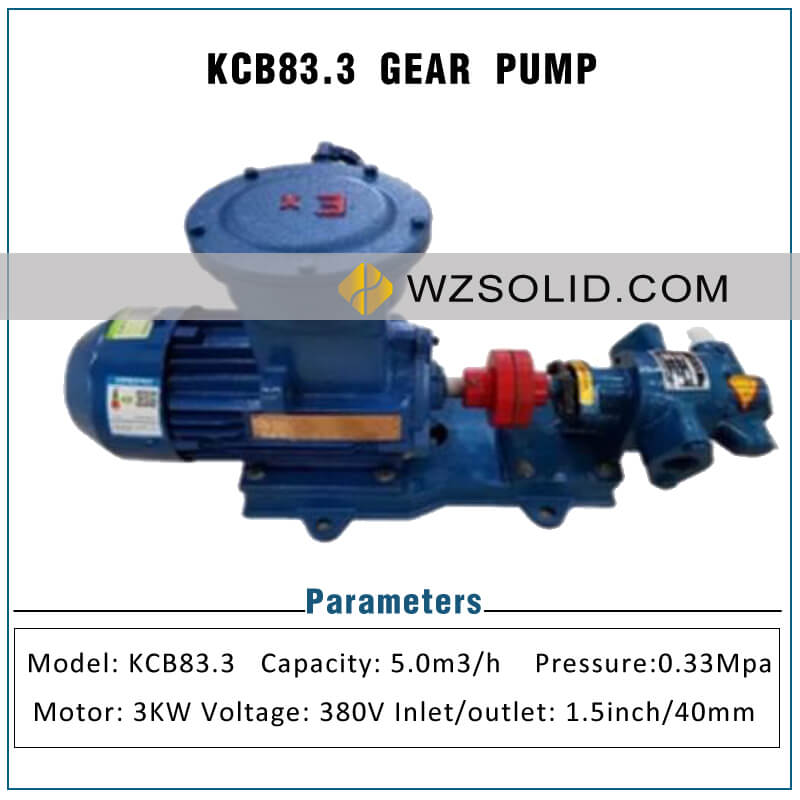

1.5 Inch Oil Pump KCB83.3 Electric Gear Pump Diesel Pump Lubricating Oil Pump Complete Set with Explosion-proof Motor

PARAMETERS

| Model NO. | KCB83.3 |

| Tooth Flank | Straight Tooth |

| Power | Electric 380V 50Hz 2.2KW |

| Applications | Diesel oil, engine oil, hydraulic oil, transformer oil, glue butter, rapeseed oil, soybean milk, soybean dregs, rapeseed oil, chemical raw material paint etc. |

| Viscosity | <300cst |

| Trademark | SOLID |

| Specification | GB/T 19001-2000 |

| HS Code | 8413602990 |

| Mesh Form | External Engaged |

| Tooth Curve | Cycloid |

| Type | Normal Line Gear Pump |

| Certification | CE, ISO |

| Temperature | 200 |

| Certificate | CE, ISO, SGS |

| Transport Package | Marine Wooden Case |

| Origin | CHINA |

This pump is suitable for conveying various oils with viscosity below 300C. s.t, such as crude oil, diesel, lubricating oil, animal and vegetable oil, etc. Equipped with copper gears, it can transport low flash point liquids such as gasoline, benzene, etc. The medium temperature shall not exceed 70C, and the operating temperature of the high-temperature resistant oil pump shall not exceed 300C. The pump itself is equipped with a safety valve, which provides safety protection when overloaded.

KCB Cast Iron or Stainless Steel External Gear Oil Pump Application

KCB Gear Oil Pump applies to transfer non-corrosive lubricating-oil or equivalent liquid without solid particle and fibre at temperature below 300oC and with the viscosity of 5× 10-6~1.5× 10-3m2/S(5-1500cSt), such as diesel oil, crude oil, engine oil, hydraulic oil etc.

If it is coupled with copper gear and ex-proof motor, it is suitable for gasoline, benzene transfer. It also fit for drink, milk, honey, vegetable oil transfer if coupled with stainless steel material.

This pump is coupled with pressure relief valve. There are cast iron, aluminum alloy and stainless steel pump body for option. The seal can be oil seal, packing seal or mechanical seal at customer's demand.

KCB Cast Iron or Stainless Steel External Gear Oil Pump features:

1. Smart and impact structure, convenient operation and maintainance.

2. Consist of gear, shaft, pump body, bypass valve and seal.

3. For high viscosity lubricant liquid transfer, low pressure, large output, up to1200L/min\

4. Good self-priming ability, so it is not necessary to pour lubricant oil before pump works.

5. Electric motor or diesel engine driven.

6. Bypass valve is built in to protect pump when pump works under high pressure.

7. Perform as transfer pump or booster pump in oil delivery system. Applied as fuel pump, lubricating pump as well.

8. Applicable in oil reserviors, pipe transfer, ships, mining sites, factories and farms.

Technical parameters:

| Type |

Diameter (inch) |

Flow | Outlet pressure (MPa) |

Suction (m) |

Motor power (KW) | |

| (m3/h) | (L/min) | |||||

| KCB18.3 | 3/4 | 1.1 | 18.3 | 1.45 | 5 | 1.5 |

| KCB33.3 | 3/4 | 2 | 33.3 | 1.45 | 5 | 2.2 |

| KCB55 3.3/3.3-2 | 1 | 3.3 | 55 | 0.33 | 5 | 1.5 |

| KCB55 3.3/5-2 | 1 | 3.3 | 55 | 0.5 | 5 | 2.2 |

| KCB83.3 5/3.3-2 | 1/2 | 5 | 83.3 | 0.33 | 5 | 2.2 |

| KCB83.3 5/5-2 | 1/2 | 5 | 83.3 | 0.5 | 5 | 3 |

| KCB200 8/3.3-2 | 2 | 8 | 133 | 0.33 | 5 | 4 |

| KCB200 12/1.3-2 | 2 | 12 | 200 | 0.13 | 5 | 4 |

| KCB200 12/3.3-2 | 2 | 12 | 200 | 0.33 | 5 | 5.5 |

| KCB200 12/6-2 | 2 | 12 | 200 | 0.6 | 5 | 5.5 |

| KCB200 12/10-2 | 2/2 | 12 | 200 | 1 | 5 | 7.5 |

| KCB300 18/3.6-2 | 3 | 18 | 300 | 0.36 | 5 | 5.5 |

| KCB300 18/3.6-2 | 3 | 18 | 300 | 0.36 | 5 | 7.5 |

| KCB483.3 29/3.6-2 | 3 | 29 | 483.3 | 0.36 | 5 | 7.5 |

| KCB483.3 29/10-2 | 3 | 29 | 483.3 | 1 | 5 | 11 |

| KCB633 38/2.8-2 | 4 | 38 | 633 | 0.28 | 5 | 11 |

| KCB633 38/8-2 | 4 | 38 | 633 | 0.8 | 5 | 22 |

| KCB960 60/3-2 | 4 | 60 | 960 | 0.3 | 5 | 18.5 |

| KCB960 60/6-2 | 4 | 60 | 960 | 0.6 | 5 | 30 |

|

KCB2000 120/3-2 |

6 | 120 | 2000 | 0.3 | 5 | 30 |

| KCB2500 150/3-2 | 6 | 150 | 2500 | 0.3 | 5 | 37 |

Precautions before using KCB gear pump oil pump:

1. Install gear oil pump:

a. Before installation, it is necessary to check whether the pump has been damaged during transportation, such as whether the motor is damp, whether the dust covers at the pump inlet and outlet are damaged, and whether dirt enters the pump chamber.

b. Before installing the pipeline, the inner wall of the pipeline should be cleaned with clean water or steam. During installation, the weight of the pipeline should be avoided being borne by the pump to avoid affecting the accuracy and lifespan of the pump.

c. The gear oil pump should be as close as possible to the oil pool; The connection parts of the pipeline must not leak gas or liquid, otherwise it may cause the phenomenon of not being able to absorb liquid.

d. To prevent impurities such as particulate matter from entering the pump, a metal filter should be installed at the suction port with a filtration accuracy of 30 mesh/in, and the filtration area should be more than three times the cross-sectional area of the oil inlet pipe.

e. It is recommended to install vacuum and pressure gauges on the inlet and outlet pipelines to monitor the working status of the pump.

f. When the oil pool is deep, the oil suction pipeline is long, or the medium viscosity is high, causing excessive vacuum, the inlet pipe can be thickened by one gear. When the oil suction pipeline is long, a bottom valve should also be installed.

2. Inspection of gear oil pump before operation

a. Are the fasteners of the pump secure.

b. Whether the rotation of the driving shaft is uniform and consistent in weight.

c. Is the valve of the inlet and outlet pipeline open.

d. Does the rotation direction of the pump meet the requirements.

e. Before initial use, an appropriate amount of medium should be injected into the pump.

3. Maintenance of gear oil pump during operation

a. Note that the readings on the pressure gauge and vacuum gauge of the gear oil pump should comply with the technical specifications specified for the pump.

b. When there is abnormal noise or excessive temperature rise during the operation of the gear oil pump, the pump should be stopped immediately for inspection.

c. In general, it is not allowed to adjust the safety valve arbitrarily. If adjustment is needed, an instrument should be used for calibration. Set the cut-off pressure of the safety valve to the pump

d. 1.5-2 times the rated pressure. 4. Pump stop

a. Cut off the power.

b. Close the inlet and outlet pipeline valves.

KCB gear pump mainly consists of gears, shaft, pump body, safety valve, and shaft end seal. The KCB gear pump has well-designed oil discharge and return grooves, and the wheel bears the minimum torque force during operation. Therefore, the bearing load of the KCB gear pump/gear oil pump is small, the wear is small, and the pump efficiency is high.